It all started with Hailed, a company with a dream of creating a wood stove that was not only functional but also aesthetically pleasing. Their vision was clear – a wood stove with a round window and a rectangular body that looked clean and seamless. All handling elements should be hidden, and the handle should reflect the round window and complement it. The stove should be wall-mounted and interchangeable with a glass box and a wood holder. The challenge was set, and we were more than excited to take on this project.

Our first step was to define the features and collect all the requirements for the stove. We wanted to ensure that we were on the same page with Hailed and that all their requirements would be met. We communicated regularly with Hailed, and their input and feedback were welcomed and incorporated into the design.

We then started designing the airflow in the wood stove, which is crucial to guarantee an efficient and clean burn of the wood. We planned baffles to redirect air and smoke, and the primary airflow was adjustable by a lever. The design of the airflow was refined during the design phase, which involved integrating the features defined in the first phase. Throughout the design process, manufacturability was a guiding principle. We aimed to find easy-to-manufacture solutions and use purchase parts that reduced assembly effort and costs.

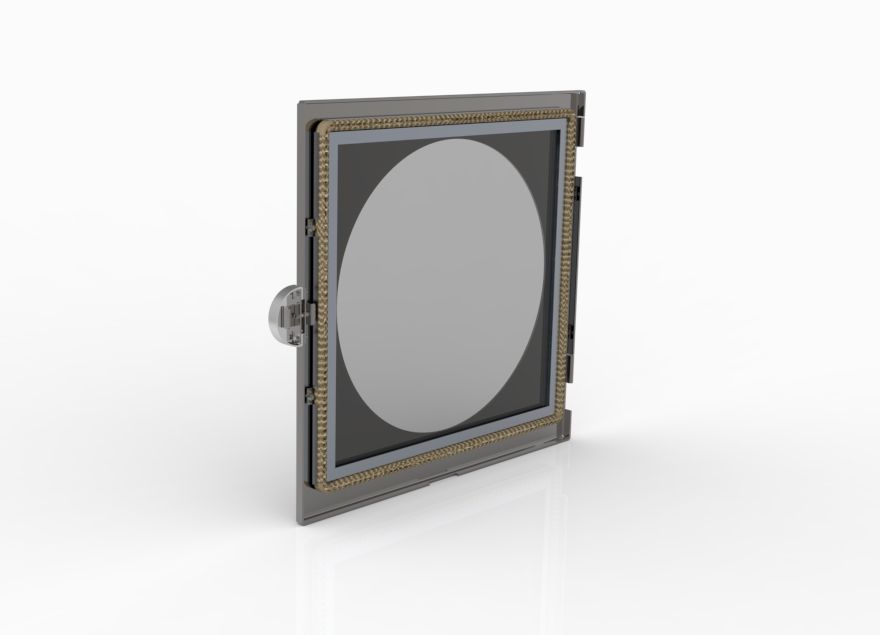

We paid attention to every detail, and the design of the latch resulted in a very aesthetic handle in which the opening and closing mechanism was hidden. The pull while opening the door supported the opening mechanism of the latch, making the handling very intuitive and easy. The round opening on the rectangular stove boosted the aesthetics and gave the user a great view of the fire. The glass and stove are self-cleaning, utilizing the flow of the heated air in the stove.

We also designed additional components, including a stylish wood holding compartment underneath or set up on top of a glass cabinet featuring the firewood inside, as well as a fully integrated cabinet for the stove and the wood. We needed to make sure every component fits with the stove, but the interfaces to connect shouldn’t show on the stove. In any combination, you won’t see the interface.

For example, we optimized the manufacturing and assembly effort for each part by reducing welding spots and optimizing bends in sheet metal parts. Parts were increasingly simplified, especially after finding the final solutions and finalizing the overall aesthetic of the stove. After finalizing the design with Hailed, we created all the necessary documents for manufacturing.

The deliverables included a specification list of requirements, a design overview including concepts, a 3D model in step format, detailed manufacturing and assembly drawings, DXF files for cutting and bending, and a bill of materials for easy procurement of purchasable parts.

The final optimizations and prototypes were done in the workshop with a resident engineer. Hailed successfully brought the product to the market, where customers can buy it now.

It was a fantastic experience to be part of the journey from the first concepts to the final product Hailed can now offer to its customers. Our collaboration with Hailed was seamless, and their input and feedback were crucial to the project’s success.

In the end, we delivered a wood stove that was functional and beautiful. The fireplace was designed to ensure the perfect airflow to burn the wood clean and efficiently, making it a piece of art in every room it is set up. It is wall-mounted and can be enhanced by additional components, making it versatile and adaptable to any living space. Check it out here:

“ARKUS engineering and especially Timm is fantastic to work with. His engineering knowledge and communication skills are second to none. He is our go to engineer for projects and can turn around high-quality work very quickly. Highly recommend.”

Dennis A., Hailed Pty. Ltd.