Vue Robotics, Inc., a leading innovator in real-time environmental monitoring, specializes in deploying advanced camera systems for multi-site management, particularly in the construction industry. These systems, such as the ARC1, provide persistent site intelligence, crucial for monitoring progress, safety, and environmental conditions on construction sites. Vue Robotics is committed to operational excellence and safety, leveraging technology to enhance routine inspections and hazard management.

Vue Robotics approached ARKUS engineering with a requirement for a bespoke mounting bracket for their innovative camera system. The bracket is needed to support the camera’s deployment across various outdoor environments, ensuring robustness, adjustability, and ease of installation.

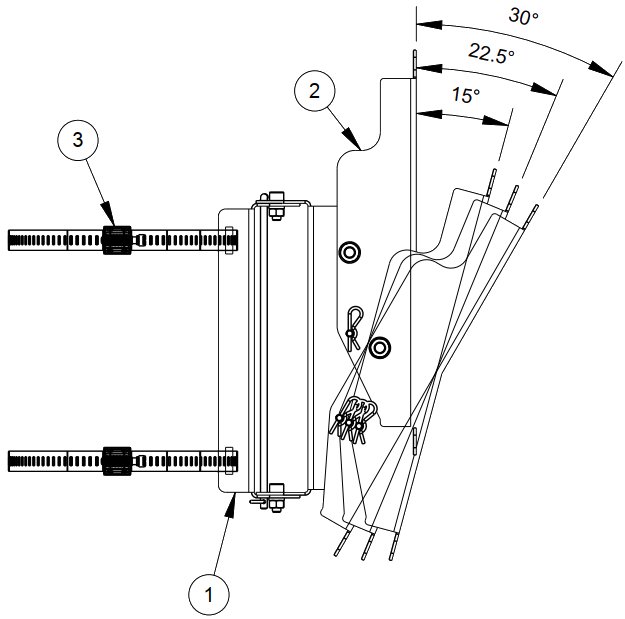

Drawing on its profound expertise in mechanical design, ARKUS developed a detailed specification that included precise geometric dimensions, material specifications, and functional mechanisms:

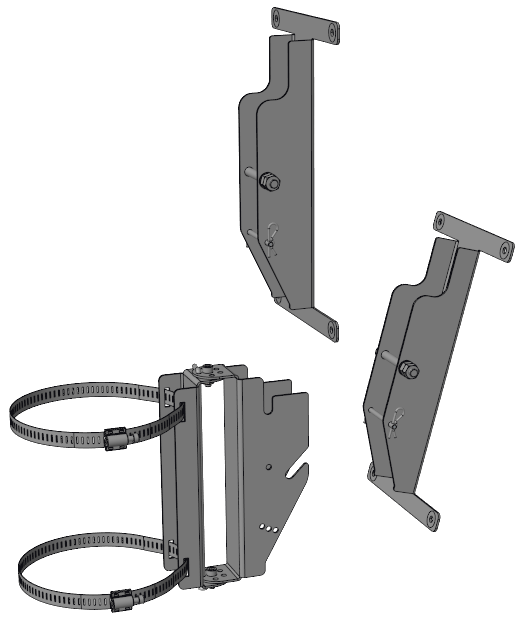

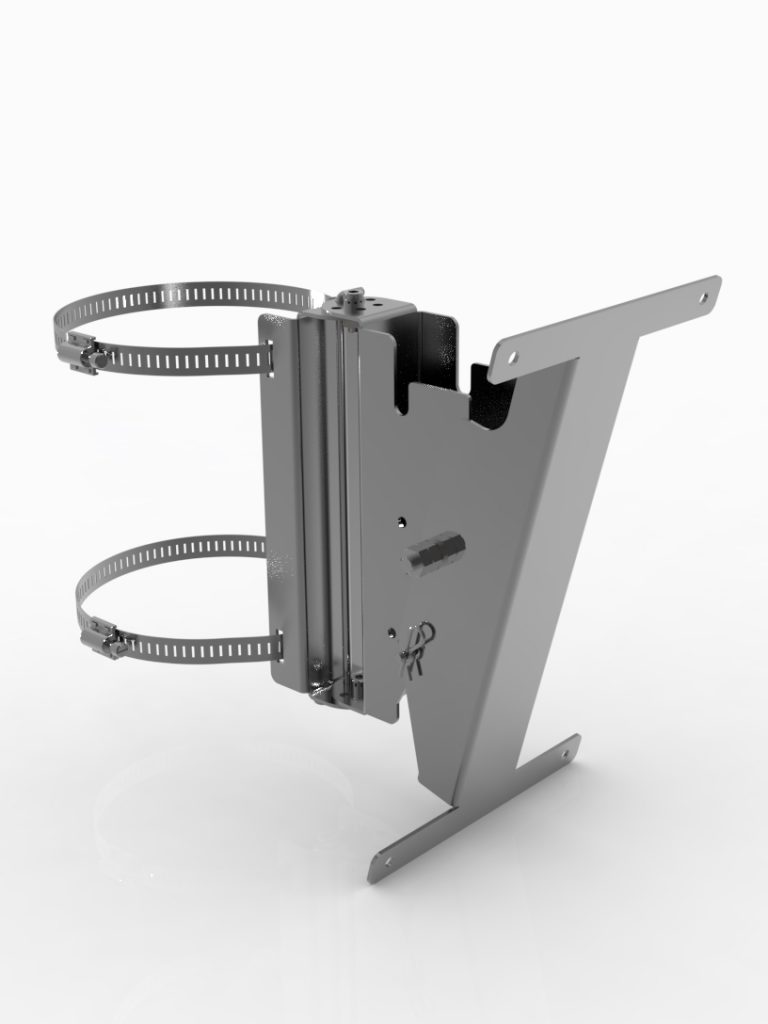

- Two-part assembly for easy single-handed installation.

- Durable stainless steel components.

- Adjustable settings for optimal camera orientation.

- Design specifications for quick installation and minimal maintenance.

ARKUS used advanced 3D modelling to create accurate visualizations of the proposed bracket, enabling the client to understand and approve the designs before proceeding to production. This modelling was crucial in refining the bracket’s functionality and ensuring all components would interact as intended. The team then produced detailed manufacturing drawings and a comprehensive Bill of Materials (BOM). The BOM outlined all purchasable parts, ensuring that production was cost-effective and that parts were readily available, minimizing potential supply chain issues.

During the manufacturing phase, ARKUS coordinated with manufacturers in the U.S., where Vue Robotics is based. To streamline the manufacturing process and accommodate local industry standards, ARKUS adapted the design from metric to imperial dimensions. This strategic adjustment facilitated using more readily available components, enhancing the product’s manufacturability and cost-efficiency. The final product, reflecting these modifications, has been successfully implemented and appreciated by Vue Robotics for its straightforward design and ease of installation.

The custom-designed bracket met all of Vue Robotics’ requirements, ensuring:

- Ease of installation, allowing a technician to install the bracket single-handedly in less than 10 minutes.

- Durability and reliability in various environmental conditions, from extreme heat to high humidity.

- Cost-effectiveness through using standard parts where possible, reducing the need for extensive custom components.

This project exemplified ARKUS engineering’s ability to deliver custom solutions that align with specific client needs, enhancing the functionality and deployment of cutting-edge technology in challenging environments. The successful design and production of the mounting bracket for Vue Robotics underscored ARKUS’s commitment to innovation, precision engineering, and client satisfaction, solidifying its role in bespoke mechanical engineering solutions.